Schleuniger StripCrimp 208

Product Benefits

- Fully programmable stripping unit with wayback and recut function

- Well-arranged 7" touch screen for fast and easy operation

- Quick-release applicator base plate for easy change-over

- Job memory for all cable parameters and functions

- Split cycle capability

- Short breakout lengths of 22 mm (0.86"

Get A Brochure

Technical Specification

Overview

The StripCrimp 208 is suitable for high precision stripping and crimping of side- and rear-feed terminals for wire cross-sections between 0.05 – 6.00 mm² (30 – 10 AWG). It is flexible, reliable, and user-friendly. It combines the standard working processes of cable processing in a single machine. Short breakout lengths of 22 mm (0.86″) – and even down to 10 mm (0.39″) using special tools – permit the processing of sensor applications. It impresses with high productivity and uniform processing quality.

That makes this strip and crimp machine an all-rounder for many applications and industries.

Key Features

- Well-arranged 7″ touch screen for fast and easy operation

- Short breakout lengths of 22 mm (0.86″) for multi-conductor cables

- Quick-change system for all standard rear-feed and side-feed applicator tools

- Ergonomically designed cable clamp facilitates cable insertion

- Optional crimp force monitoring

- Optional reject part cutter with crimp force monitoring

Infinitely Versatile

A particular Schleuniger speciality is the customer-specific tooling of applicators. Our crimping specialists have a long history of finding solutions for even the most difficult to process terminals. Customers from all over the world enjoy the benefits of working with Schleuniger high precision applicators. The quick-change applicator system allows the operator to seamlessly change tooling with very little downtime. The user can program piece and batch counters and for special jobs, the machine can be switched to different modes such as “strip only”.

Flexibility and User-friendliness

All stripping parameters and special functions are programmable through a user-friendly operating panel that utilises Schleuniger’s new software. Key features include:

- Programmable processing parameters: cable cross section, correction value, blade dwell time, blade way back, re-cut, strip length, strip position, multiple pull-off, press speed

- Counter functions, language selection, unit of measure, crimp force monitoring activation, pneumatic terminal feed, processing modes (strip only, crimp only, strip and crimp), user account management, diagnostic functions

- Electric creep speed (left/right) with home position indicator, automatic home position function

- Micro-adjustable crimp height setting

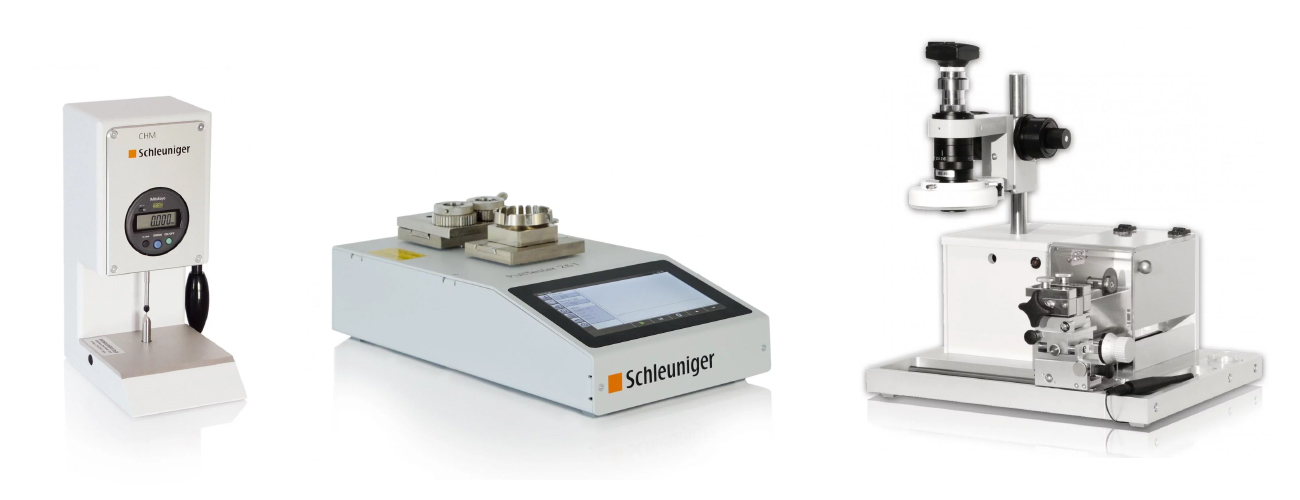

Quality Assurance

Turner Electronics offers a range of products for quality assurance and traceability of quality data. From crimp force monitoring, crimp height measuring and pullforce testing devices to fully integrated networks including software for central data management and analysis.

Options

- Crimp force monitoring with ACO 08

- Reject part cutter with ACO 08 crimp force monitoring

- Terminal band chopper

- Pneumatic valve for control of pneumatic tools

- Terminal oiler

- Paper winder

- Foot pedal

- 30 mm (1.18 “) stroke instead of 40 mm (1.57 “) standard stroke