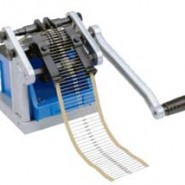

Schleuniger Cutbend Machine

Get A Brochure

More than 35,000 samples of the proven CUTBEND machine for cutting and bending the axial leads for taped components are operated worldwide. It is easy to use, cost effective, and can process up to 40,000 components per hour. The CUTBEND can easily be adjusted and readjusted to different components and dimensions.

More than 35,000 samples of the proven CUTBEND machine for cutting and bending the axial leads for taped components are operated worldwide. It is easy to use, cost effective, and can process up to 40,000 components per hour. The CUTBEND can easily be adjusted and readjusted to different components and dimensions.

The easy-to-replace cutting and bending wheels allow very thin (0.5mm) or very thick (1.2mm) leads to be processed. The well designed mechanism avoids axial tensile stress during processing and damage to delicate components by the slight staggering of the processing of both lead ends. The CUTBEND can be mounted to any table thanks to it’s screw clamp. The numerous accessories allow a full component processing system to be created on the basis of the CUTBEND.

The adjustment tool supplied as standard equipment, is used to transfer the distances between the holes of the board and for quick and accurate setting of the CUTBEND.

Cutbend Specifications

- Dimensions (without crank): L 175mm (6.9″), W 145mm (5.7″), H 160mm (6.3″)

- Weight (complete): 1.9kg (3.9 lbs)

- Crank Length: 160mm (6.3″)

- Output: up to 40,000 components per hour

- Maximum component diameter for all models: 14mm