Telsonic Telso®Splice TS6

Product Benefits

- Cross sections from 2.5 mm² to 75 mm²

- Large cross-sectional range with the same machine

- Easy to operate and maintain

- Production server for distributing orders between Telso®Splice systems

- Quality check with Telsonic Quality Control Center TQCC

Get A Brochure

The Telso®Splice TS6 is a tried-and-tested, sophisticated wire welding system. With its robust design, the TS6 covers the higher cross-sectional range. The Telso®Splice features highly intuitive touchscreen operation. Jobs, splices and sequences can be defined easily on the screen or loaded via the Telso®CON data interface. Integration into MES environments is done via corresponding software plugins; for example, for the 4Wire CAO from Di.IT or customer-specific systems. Alongside the standard limit value monitoring, a bad parts cutter, anti side-splice accessory, wire stops and a user and rights management system help guarantee the highest level of quality.

Area of application

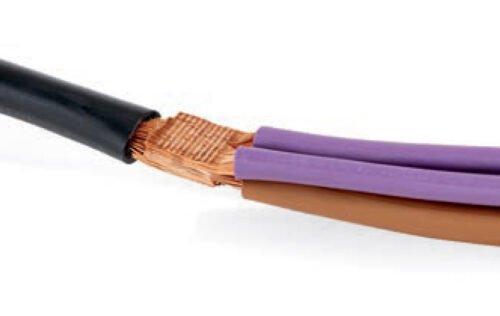

Ultrasonic joining technology is widely used to produce reliable electrical connections in the automotive industry, as well as in a broad range of other fields. The benefits of ultrasonic wire splicing include lower electrical resistance, improved cost efficiency and a high level of protection against corrosion. Typical applications include wire splicing in preproduction and wire harnesses on assembly boards or the compaction of wires. Copper-to-copper and copper-to-aluminium combinations can be welded with the same machine.

Processing Capabilities

- Single splices and splice sequences

- High-voltage multi-conductor cables

- Twisted data cables

- Inline and end splices

- Center-strip splice

- Wire compaction

- Copper and aluminium wires