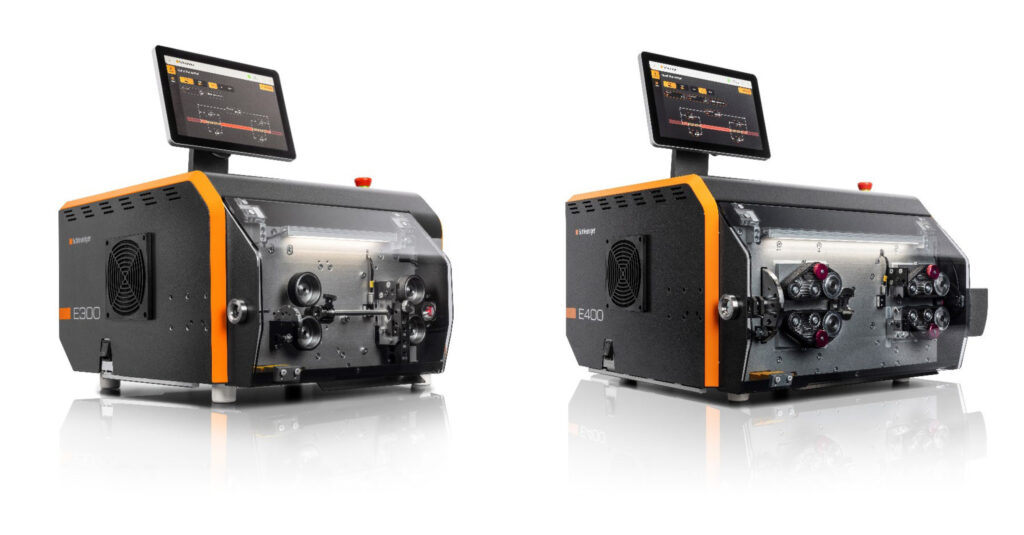

New Schleuniger Cut & Strip Family E300 and E400

The new generation of Schleuniger Cut & Strip machines impresses with its high performance, optimised operability and outstanding process reliability. The E300 and E400 are the ideal cut and strip machines for the lower cross section ranges. Thanks to their versatility, they are ideal for a wide variety of applications from cables in industrial applications, cable harnesses in the automotive and aircraft industries, control cabinets, household appliances, telecommunications or consumer electronics.

-

Fast and reliable stripping of wires and cables from 0.05 to 16 mm2

-

New intuitive user interface and software

-

10” widescreen monitor with Quick-Run Mode

-

Programmable clamping axis for greater precision

The E300 and E400 cut and strip machines can be combined with many peripherals, including existing Schleuniger machines, so you can set up automatic processing lines. Possibilities include processes such as feeding, marking, hot stamping, and coiling.

E300 Overview

The Cut & Strip Family E300 cut and strip machine impresses with high performance, optimised operability and outstanding process reliability. It processes wires, tubing, ribbon and multiconductor cables as well as insulation such as PVC, PUR or Teflon in high-precision quality. Standard applications include the stripping of the outer jacket in several steps, as well as full and partial strips – also on both sides – with conductor cross sections from 0.05 to 10 mm² (36 to 8 AWG) and cable diameters from 0.3 mm to 8.0 mm (0.012″ to 0.31″). Different belt materials and the included short piece kit allow a wide range of applications. Blades and guides of the predecessor model EcoStrip 9380 are compatible.

E400 Overview

The Cut & Strip Family E400 cut and strip machine impresses with its high performance, optimised operability and outstanding process reliability. Standard applications include the stripping of the outer jacket in several steps, as well as full and partial strips – also on both sides – with conductor cross sections from 0.14 to 16 mm2 (26 to 6 AWG) and cable diameters from 0.8 to 12.5 mm (0.032″ to 0.49″). It processes wires, tubing, ribbon and multiconductor cables as well as insulation such as PVC, PUR or Teflon in high-precision quality. Blades, belts and guides of the predecessor model MultiStrip 9480 are compatible.

Please contact us for a quote or to arrange a demonstration on 020 8668 0821 or email sales@turnerelectronics.co.uk