Schleuniger Cut & Strip Family E300

Product Benefits

- Economical price point

- Excellent performance and precision

- Programmable clamping axis

- 10" color touchscreen

- Easy-to-use interface and operation

Get A Brochure

Technical Specification

Overview

The Cut & Strip Family E300 cut and strip machine impresses with high performance, optimised operability and outstanding process reliability. It processes wires, tubing, ribbon and multiconductor cables as well as insulation such as PVC, PUR or Teflon in high-precision quality. Standard applications include the stripping of the outer jacket in several steps, as well as full and partial strips – also on both sides – with conductor cross sections from 0.05 to 10 mm² (36 to 8 AWG) and cable diameters from 0.3 mm to 8.0 mm (0.012″ to 0.31″). Different belt materials and the included short piece kit allow a wide range of applications.

- New intuitive user interface for efficient operation

- Software assistance for quick troubleshooting

- Programmable clamping axis for greater precision

- Tool-free exchange of guides

Application Flexibility

Thanks to the versatility, the E300 is perfect for a wide range of applications from cables in industrial applications, cable harnesses in the automotive and aircraft industries, control cabinets, household appliances, telecommunications or consumer electronics. The E300 can be combined with a wide range of peripherals so you can set up automatic processing lines. Existing Schleuniger peripherals are compatible. Possibilities include processes such as feeding, marking, hot stamping, and coiling.

Programmable Feeding Unit

The contact pressure on the feeding unit is programmable. This allows for very fine and targeted adjustments. The E300 is equipped with a two-in-one quick-change feeding unit suitable for roller drives, including a short piece kit for the processing of short cables. On the E300, changing the feeding unit to the short piece kit is software assisted. The gripping axis is programmable and ensures accurate transport of the cable.

Easy To Use

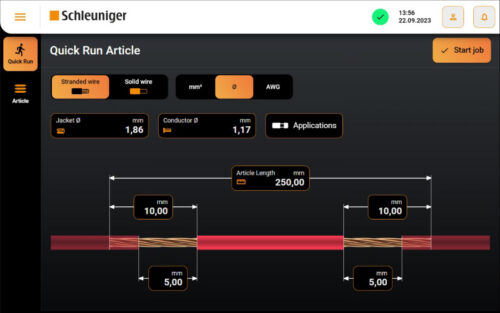

On the 10-inch colour touchscreen, the functions are neatly arranged. The focus on the essential parameters and the user-friendly display facilitate operation. The intuitive interface of the S.Drive software facilitates the creation of jobs and article programs, and increases overall performance. Predefined and verified default parameters support quick creation of processing jobs.

The software will guide the operator through setup and assist with troubleshooting providing information on the HMI. If required, error messages can be exported and submitted to Schleuniger Service. This cuts down on downtimes and expenses for external service technicians.

Processing Capabilities

- Cut to Length

- Full or Partial Strip Left and Right

- Jacket Stripping of Thin Insulations

- Jacket Stripping of Multi-Conductor Cables

- Multistep stripping

- Single Wires

- Flat Cable

- Tubes and Pipes

- Wire Marking

Basic Equipment

- 10″ color touchscreen

- LED light

- Air Jet unit

- Set of V-shaped blades

- Swivel guides: inner diameter 2, 4, 6, 8, 10 mm

- 2 steel rollers and baffle for short piece kit

Options

- Cable jam detector

- Various radius blade sets

- Toolbar with magnetic holder for accessories

- Software Feature Marking (available from Q3/2024)

Blades and guides of the predecessor model EcoStrip 9380 are compatible.