Schleuniger PowerStrip 9580

Product Benefits

- Innovative machine control for high productivity and process reliability

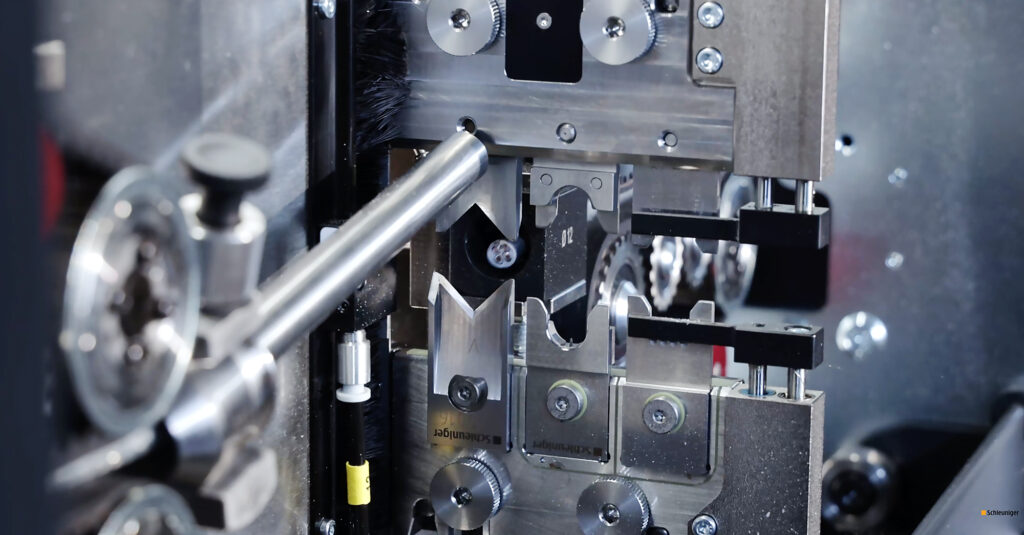

- SmartBlade system for quick changeovers of entire blade cartridge sets within seconds

- Simultaneous activation of multiple axes

- Powerful servomotors for high feed rates and pull-off forces

- Toolless guide changeovers

Get A Brochure

Technical Specification

Overview

The PowerStrip 9580 processes a wide range of applications and impresses with its modular, flexible and retrofittable machine concept. Excellent production output with high-precision processing characterises this automatic cut & strip machine.

The PowerStrip 9580 automatic cut & strip machine was designed with a focus on high-precision processing, excellent production output and a high degree of production flexibility. Powerful servo drives ensure fast feeding speeds and high stripping forces. An intelligent control unit guarantees short cycle times and repeatable high-quality performance. A sophisticated safety concept, short changeover times and modern, intuitive machine operation round off the exclusive machine profile.

Application Range

Discrete wires with cross sections up to 70 mm² (2/0 AWG), shielded cable and complex multiconductor applications can be processed in one automated operation. Processing modules, such as the programmable cutter head system, rotary incision unit and moveable right exit guide allow you to configure your PowerStrip 9580 according to your application requirements now or in the future.

The optional cutting unit, including the SmartDetect quality monitoring system, prevents defective cables from being incorporated into an end product. The sensor-controlled system monitors the complete stripping process in real time, detects any contact between stripping blade and the inner conductor and contributes to improved production quality with no loss of performance.

Shielded and Heavy-Duty Cables

Whether it is for securing a safe power supply of a car battery or for powerful and robust applications with extremely high safety provisions to prevent accidental short circuits in hybrid and electric cars: Battery and high-voltage lines require extremely precise and robust construction as well as complete quality control. The PowerStrip 9580 is perfectly suited to cut and strip shielded and high-voltage cables up to 16mm O.D. used in the automotive, railway, transport, aerospace and defence industry.

Options

Different options add processing capabilities to your PowerStrip 9580 or make working with the machine even easier. Examples are the universal slitting unit, different blade types, or the modular rack system for comfortable operation. The intelligent design with PowerSystem and SmartBlade guarantees maximum flexibility today and in the future.

Processing Modules

The PowerStrip 9580 is available in 4 basic configurations, combining processing with functional modules to cover a wide range of wire processing applications. All basic models can be retrofitted with other PowerSystem functional modules and options. The modules integrated in the basic models can also be retrofitted or replaced in the future if your application requirements change.

- PowerStrip 9580 S with single-blade cutting unit

- PowerStrip 9580 M with flexible SmartBlade multiblade cutting unit

- PowerStrip 9580 SR with single-blade cutting unit and additional rotary cutting unit

- PowerStrip 9580 MR with flexible SmartBlade multiblade cutting unit and additional rotary cutting unit

Programmable Processing Parameters

- Cutting and stripping with full and partial pull-offs, left and right

- Multistep jacket pull-offs

- Multistep stripping

- Jacket stripping of multiconductor cables

- Jacket stripping of extremely thin insulations

- Jacket and inner conductor stripping

- Trimming, separating and stripping

- Multistep jacket stripping with longitudinal slits and windows

- Multistep stripping of shielded cables (with or without shield

processing)