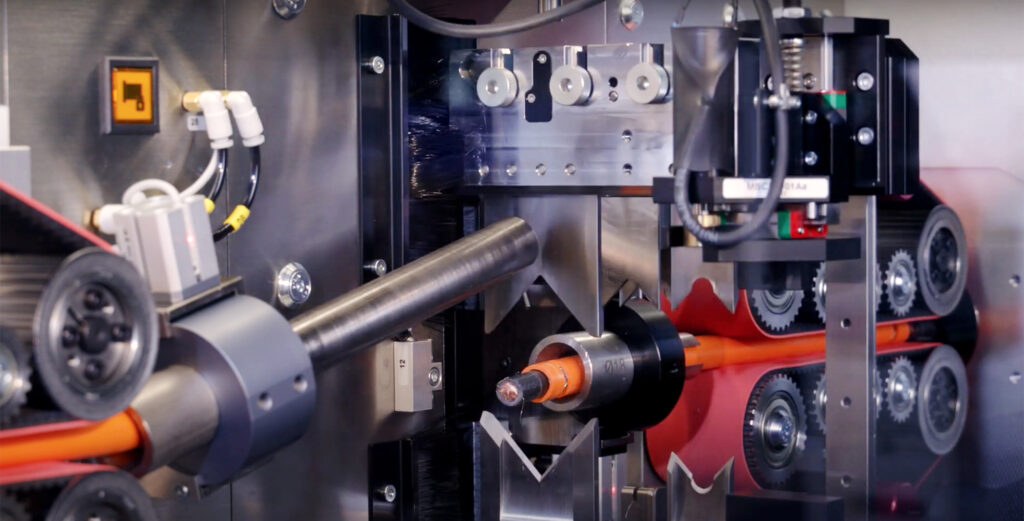

Schleuniger MegaStrip 9680

Product Benefits

- High-precision cutting unit with SmartDetect quality-monitoring system

- Modular design allows future upgrades

- Precise Rotary Incision Unit with Automatic Centering

- User-friendly software and intuitive operation via the 10” colour touch screen

- High flexibility thanks to the SmartBlade system

Get A Brochure

Technical Specification

Overview

The MegaStrip 9680 is an automatic cut and strip machine for processing single core wires, multiconductor cables and shielded cables up to 35 mm (1.38″) in outer diameter. The modular design and the possibility to connect various peripherals – either from the Schleuniger product range or from third-party suppliers – make this machine a true all-rounder.

- Two modular machine designs with additional options offer an extensive processing range for larger diameter cables.

- Precise, multistep stripping thanks to the Schleuniger multiblade cutting unit and SmartDetect quality monitoring system

- High flexibility thanks to the SmartBlade system with exchangeable cartridges for the quick changeover of complete blade sets

- Extensive libraries for recurring cable end types and processing methods simplify programming

- Economical production and waste avoidance using up to two independent inkjet printers positioned downstream of the cutter head

- Compatible with MES CAO via SMG Server and CAYMAN software

Application Range

Discrete wires with cross sections up to 120 mm² (4/0 AWG) or optional 300 mm² (MCM 600), shielded cable and complex multi-conductor applications can be processed in one automated operation. The MegaStip 9680 is available in 2 basic configured models:

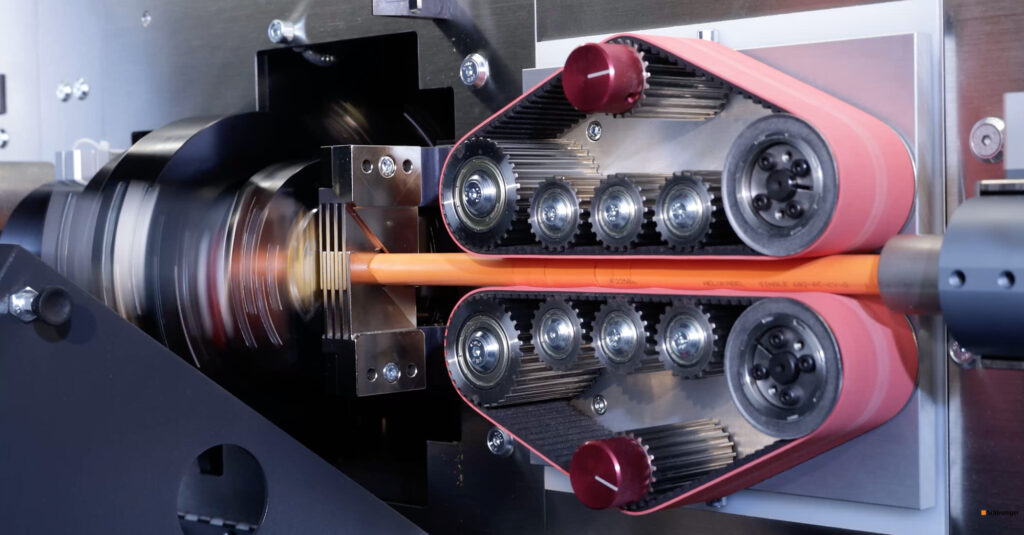

- M version with the freely programmable indexing multiblade cutter head

- MR version with additional rotary incision unit for precise shield cutting

Both model versions are compatible with the CAYMAN cable processing software and the CAO planning software (Manufacturing Execution System), enabling integration into different networks. The MegaStrip 9680 is optimised for maximum production output. Powerful servomotors ensure high feed rates and pull-off forces. Colour-coded guides and toolless guide changeovers allow for record-breaking changeover times. Sensor monitoring and the optional SmartDetect system ensure smooth production processes, quick fault rectification, and minimal material waste.

Heavy-Duty / High-Voltage Cables

Whether it is for securing a safe power supply of a car battery or for powerful and robust applications with extremely high safety provisions to prevent accidental short circuits in hybrid and electric cars: Battery and high-voltage lines require extremely precise and robust construction as well as complete quality control. The MegaStrip 9680 is perfectly suited to cut and strip heavy-duty and high-voltage cables used in the automotive, railway, transport, aerospace and defence industry.

Concept

The MegaStrip 9680 M model features Schleuniger’s patented multiple blade position cutter head for multistep operations. The MR model adds a rotary incision unit for high-precision shield cutting. Both models come standard with the SmartBlade system, allowing quick blade changeovers in seconds. The machine can operate with up to 2 different inkjet marking systems. The print head positions are after the cutter head to prevent any waste pieces.

Processing Capabilities

- Cut to length

- Discrete wire stripping

- Full or partial strip left and right

- Jacket and inner conductor stripping

- Jacket stripping of extremely thin insulations

- Jacket stripping of multiconductor cables

- Multilayer stripping

- Multilayer with shield processing (coax, hybrid, etc.)

- Multistep jacket stripping with inner conductor stripping and window slitting

- Multistep stripping

- Trimming, separating and stripping of individual zipcord conductors

- Window stripping

- Wire marking