Schleuniger EcoCut 3300

Product Benefits

- Excellent price/performance ratio

- Precise and repeatable results

- Easy to program and operate (menu-guided)

- All-electric operation

- Fast and quiet transport system

Get A Brochure

Technical Specification

The EcoCut 3300 is designed to automatically cut all kinds of material including wire, cable, round material such as tubing, flat ribbon and Glass Fiber Optic (GOF) cable. This flexible machine processes wire up to 16 mm² (6 AWG), cuts round material up to 12 mm (0.47”) O.D. and cuts flat material up to 100 mm (3.94”) wide.

The EcoCut 3300 is easy to program and operate due to its menu-guided programming and operation as well as its intuitive handling. An additional quadruple cable guide allows multiple cables to be processed simultaneously thus significantly increasing production. The EcoCut 3300 can be used as a stand-alone machine or can be integrated into a processing line. The EcoCut 3300 is electronically controlled and features several interfaces for peripheral components. The electrically driven rollers feed the material in increments of 0.1 mm (0.004“) to the universal cutting unit. The cutting unit is electrically driven and position controlled.

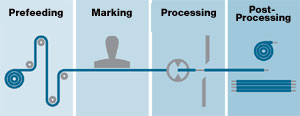

Automatic Inline Processing

The EcoCut 3300 can easily be integrated with a prefeeder and a hot stamp marker. Interfaces for inkjet printing and post-processing equipment are optionally available.

| Prefeeding |

|

| Marking |

|

| Processing |

|

| Post-Processing |

|