Schleuniger UniCrimp 208

Product Benefits

- Easy and intuitive operation via 7" touch screen

- Extremely powerful with a crimp force of 33 kN (3.3 tons)

- Quick-change system for all standard rear-feed and side-feed applicator tools

- Ergonomic design facilitates cable insertion

- Optional crimp force monitoring

Get A Brochure

Overview

The UniCrimp 208 combines the quality features of the proven Schleuniger crimp presses with a modern and user-friendly design. The well-arranged 7″ touch screen enables easy and direct operation. With a crimp force of 33 kN (3.3 tons), the UniCrimp 208 reliably connects all rear-feed and side-feed banded terminals to a conductor with high quality and speed. The welded machine base provides the necessary stability for it.

That makes this crimp machine an all-rounder for many applications and industries.

Key Features

- Easy and intuitive operation via 7″ touch screen

- Extremely powerful with a crimp force of 33 kN (3.3 tons)

- Quick-change system for all standard rear-feed and side-feed applicator tools

- Ergonomic design facilitates cable insertion

- Optional crimp force monitoring

Infinitely Versatile

All common mechanical or pneumatic universal crimp tools and the corresponding terminal material can be used. The convenient, space-saving safety shield and quick-change applicator system allows the operator to seamlessly change tooling with very little downtime. The machine speed is variable, the switch-on point of the pneumatic valve, the stop point and the speed in split cycle are programmable also. The optional ACO 08 crimp force monitoring enables a fully integrated evaluation for quality assurance that can be viewed directly on the display.

Flexibility and User-friendliness

All parameters and special functions are programmable through a user-friendly operating panel that utilises Schleuniger’s new software. Key features include:

- Reel holder and contact guide plate for rear-feed and side-feed tools are identical

- Electric creep speed (left/right) with home position indicator

- Automatic home position function

- Micro-adjustable crimp height setting

- Counter functions (total counter, piece counter and batch counter), settings (speed, crimp force monitoring activation, pneumatic valve, and split cycle) as well as the language selection are programmed via an operating panel, and shown on a display

Quality Assurance

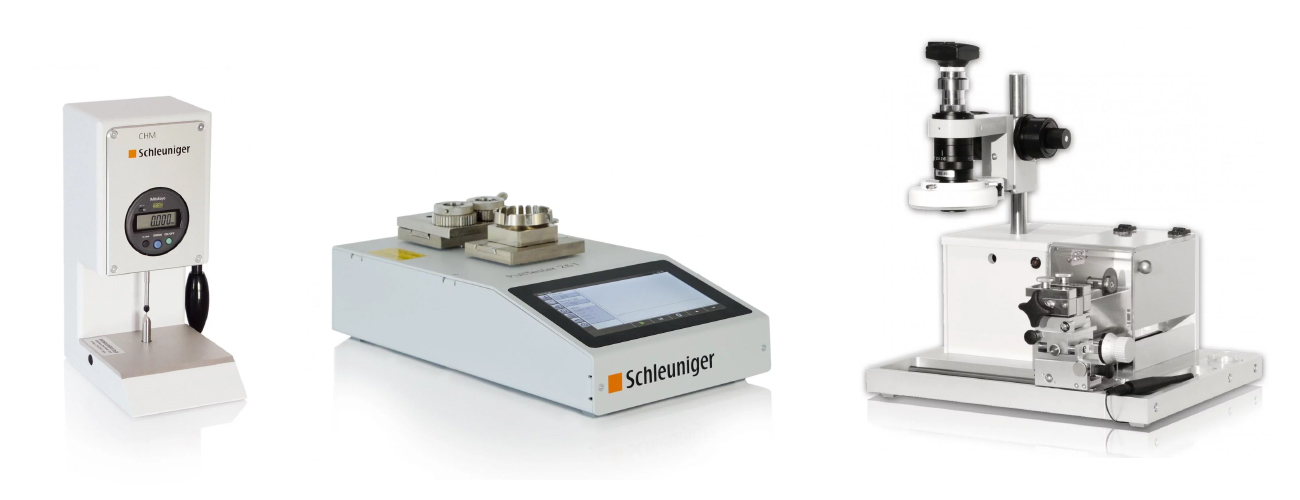

Turner Electronics offers a range of products for quality assurance and traceability of quality data. From crimp force monitoring, crimp height measuring and pullforce testing devices to fully integrated networks including software for central data management and analysis.

Options

- Crimp force monitoring with ACO 08

- Terminal band chopper

- 30 mm (1.18”) stroke instead of 40 mm (1.57”) standard stroke

- Pneumatic valve for control of pneumatic tools

- Terminal oiler

- Paper winder